Understanding Pesticide Drift and Drift Reduction Strategies

EB0233, 2022

Amy Bowser, MSU Extension Pesticide Education Technician

Cecil Tharp, MSU Extension Pesticide Education Specialist

Pesticide drift is a reality all pesticide applicators eventually face. Reducing drift is an important aspect of applying pesticides as the impacts of drift can be severe. This publication will help pesticide applicators understand the different kinds of drift, as well as present proven strategies for reducing drift in pesticide applications.

Up to 70 million pounds of pesticides are lost through drift each year (US EPA). Not only is this a problem for pesticide applicators as it reduces the efficacy of the pesticide application and wastes money, the lost pesticides can also cause severe impacts to humans, the environment and non-target sites. Drift cannot be eliminated from pesticide applications, but it can be effectively reduced through understanding the pesticide product, application equipment, local site characteristics and weather conditions.

Pesticide drift is the movement of a pesticide away from the target location through air as a droplet, vapor or with soil particulates. Drift usually occurs during or directly after an application; however, drift can take place hours or days later. The pesticide applicator is responsible for recognizing environmental conditions conducive to drift and areas vulnerable to potential drift prior to application. The applicator should carefully consider pesticide formulations, application equipment, weather conditions, sensitive sites, non-target organisms and the potential impacts related to the toxicity of the pesticide when considering drift. Reading the label can give an applicator insight into determining what precautions should be taken to reduce drift-related impacts.

Impacts of Pesticide Drift

When pesticides drift out of a target area, they can cause non-target impacts (Figure 1). Human health may be affected if pesticides contact agricultural workers, homes or other areas where people are present such as schools, hospitals, and residential areas. Water bodies can be contaminated by pesticide drift which can impact drinking water and negatively impact aquatic organisms and fish. Wildlife and other animals can be harmed by pesticide drift, as well as pollinators sensitive to certain kinds of pesticides. Nearby crops which may not be registered for certain pesticides could be harmed or become unsellable if exposed to drift. If widespread damage occurs valuable pesticide registrations could be lost. If you are responsible for pesticide drift and non-target impacts occur, you are liable. At the very least, any pesticide that travels out of the target area results in wasted money and does not control the target pest, leading to the need for additional pesticide applications and further expenditures.

Figure 1. Herbicide drift damage to winter wheat field (Bernard King/Alamy Stock Photo).

Types of Drift

Spray Drift

Spray drift occurs during a liquid pesticide application when droplets of the pesticide move through the air and land off the intended site. This type of drift can happen from all types of pesticide applications, from hand sprayers used on the ground to aerial applications from planes (Figure 2). Spray drift is often worsened when nozzles emit smaller spray droplets, called driftable fines, that are vulnerable to movement through the air. This is the most common type of drift.

Figure 2. Spray drift can occur from all types of pesticide equipment and often occurs from fine particles of product moving with air to a non-target location (Mike Mareen/Adobe Stock).

Vapor Drift

Vapor drift occurs when a pesticide volatilizes from a liquid or solid into a gas and moves offsite with air currents. Some pesticides are more volatile than others depending on their vapor pressure. Weather conditions play a large role in vapor drift. High temperatures and low humidity will increase volatilization.

Vapor Drift Case Study

In 2016, genetically modified dicamba-tolerant cotton and soybeans were put on the market and have since been used widely in the Midwest and South. This technology allows farmers to spray dicamba over fields to control weeds while their crops go unharmed; however, dicamba is known to easily volatilize and travel far off site through vapor drift if used improperly (for example: spraying when temperatures are too high; using improper nozzles; or not using low-drift formulations). In 2017, more than 2.5 million acres were estimated to be damaged from off-target movement of dicamba, according to data compiled by a University of Missouri researcher (Figure 3). Even new formulations marketed as low-drift products have caused non-target damage due to the difficulty of following strict application criteria. In one case, a peach grower suffered irreparable damage to his 1,000-acre peach orchard. His case went to court and he was awarded $265 million dollars in damages from the chemical manufacturers.

Figure 3. Dicamba vapor drift damage to soybeans (Kevin Bradley/University of Missouri).

Particle Drift

Particle drift occurs when pesticide active ingredients move with solid particles to off-target sites during or after a pesticide application. These particles may consist of pesticide granules or dust but can also consist of pesticide residue on soil or plant particles. Figure 4 shows a sugar beet field in Eastern Montana impacted by particle drift. The oilfield operator sprayed a sterilant around the oilfield equipment to control weeds. Contaminated soil particles traveled offsite to the surrounding sugar beet field preventing crop growth and impacting yield.

Figure 4. Particle drift damage to a sugar beet field (Shelley Mills/MSU).

Selecting the Proper Pesticide for Minimizing Drift

Reading the Pesticide Label

Reading the pesticide product label is the first step applicators should take to reduce drift from pesticide applications. Many labels have a section titled “Precautions for Avoiding Spray Drift,” which outlines information including temperature thresholds, minimum and maximum wind speed, spray droplet size, spray release height and buffer zones. Applicators should pay attention to droplet size requirements on the label as this will indicate whether drift-reducing nozzles may be used to increase droplet size, thereby significantly reducing drift. When a product label lists specific modifications for drift mitigation or lists sensitive areas, the applicator must follow the requirements and adjust their application to reduce drift.

Choosing a Low-Volatility Pesticide

Choosing a low-volatility pesticide can greatly decrease the amount of vapor drift from a pesticide application. One good example is 2,4-D ester which is highly volatile and should not be used when temperatures are high. Instead applicators can use 2,4-D amine which has low volatility and can be used under a wider range of environmental conditions. Vapor pressures for pesticide active ingredients can be found on the National Pesticide Information Center website at: http://npic.orst.edu/ingred/active.html.

Choose a Pesticide Product that Allows the Use of Large Droplet Sizes

Larger droplets reduce drift when compared to finer droplets. Reducing pressure will increase droplet size, however a 50–90% reduction in drift can be achieved by increasing droplet size with the use of low-drift nozzles. Switching to low-drift nozzles may not be possible with many contact pesticide formulations, select fungicides and insecticides that require smaller droplets to achieve more coverage. By assessing the droplet size required on the pesticide label, an applicator can determine the relative drift potential of the pesticide.

Table 1 shows droplet sizes and the time it takes to fall ten feet and the distance traveled

in a three mile per hour (mph) wind. As droplet size increases, the time to fall and

distance traveled decreases, potentially minimizing drift.

Using low-drift nozzles can reduce drift significantly when compared to conventional

nozzles, however many operate at higher pressures (be sure to follow manufacturer

guidelines for all nozzles). See the section on low-drift nozzles for more information.

|

Droplet

|

Width (µm)

|

Time to Fall 10 Feet

|

Travel Distance in 3mph Wind

|

|---|---|---|---|

|

Fog

|

5

|

66 minutes

|

3 miles

|

|

Very Fine

|

20

|

4 minutes

|

1100 feet

|

|

Fine

|

100

|

10 seconds

|

44 feet

|

|

Medium

|

240

|

6 seconds

|

28 feet

|

|

Coarse

|

400

|

2 seconds

|

8.5 feet

|

|

Extra Coarse

|

1000

|

1 second

|

4.7 feet

|

Louisiana State University, 2019.

Considerations to Minimize Drift

Understanding the Role of Weather on Drift

Weather conditions significantly affect drift. Temperature and humidity impact the amount of pesticide volatilization while wind influences where and how far the pesticide will travel. Under low humidity and high temperatures pesticides can volatilize very quickly. Current and forecasted temperatures should be below 85°F to reduce volatilization of almost all products. Additionally, be careful applying highly volatile pesticides if the relative humidity is below 50% during high temperatures. Wind speed should be between three and ten mph when spraying. Wind direction will determine the buffer distance from sensitive sites, with less distance needed if wind is moving away from sensitive sites. Wind speeds less than three mph may be acceptable only if a temperature inversion is not present, as explained below. Purchasing a wind meter is recommended to get accurate readings.

Temperature Inversions

Applicators in Montana should be aware of temperature inversions, as some of the calmest weather conditions can be the worst for applying pesticides. An inversion occurs when the air temperature at the earth’s surface is cooler and denser than the air above, thus creating stagnant atmospheric conditions. The larger the difference in temperatures, the more severe the inversion. In normal atmospheric conditions air movement is vertical, however during an inversion the air movement is non-existent or lateral. When you spray while there is an inversion, fine (200 microns or less) pesticide droplets hang in the air instead of settling. When wind speeds increase later in the day, the suspended droplets can move miles off-site causing non-target impacts. Inversions are common occurrences and can happen at any time of day, however they often start at dusk and continue until morning when the sun starts to heat the earth’s surface.

You can identify an inversion by several climatic factors. Wind speeds will be less

than three mph, there often are few to no clouds in the sky usually accompanied by

a high-pressure system, low humidity, dew or frost on the field, and smoke or dust

hanging in the air (Figure 5). Nozzles producing large droplets will give some application flexibility, however

all nozzles produce some fine pesticide droplets that will be carried by an inversion.

Inversions can be measured or tested for in a few different ways. Inversion probes

may be purchased which detect thermal inversions and measure air temperature at boom

height (Figure 6). The meter clearly states if there is an inversion present. Alternatively, you can

measure the air temperature at two different locations above the ground. Measure at

6–12 inches above the soil and again at 8–10 feet above the soil. If the 8–10-foot

measurement is higher in temperature than the 6–12-inch measurement, there is an inversion.

The thermometer must be shaded while measuring to not be influenced by solar radiation.

Additionally, you can use smoke or dust to determine if there is an inversion. If

the smoke hangs in the air or moves away slowly and laterally without dissipating,

there is likely an inversion. A similar method is to drive down a dirt road and if

the dust hangs in the air and does not settle, there is likely an inversion.

Figure 5. An inversion can often be identified by low lying clouds, dust or smoke. This often occurs in the morning before dawn (Edan/Adobe Stock).

Figure 6. SpotOn Inversion Meter (Innoquest Inc. 2018).

Drift Retardants

Drift retardants can be added to your spray tank as an adjuvant to increase the viscosity of the spray solution reducing driftable fines. This type of drift reduction method should not be solely relied upon as the performance is variable and is not as effective as other methods described in this publication. If using a drift reducing adjuvant, applicators should select only products recommended by professionals. Some drift adjuvants heighten droplet movement when using certain low-drift nozzles, be sure to refer to the product specification sheet for compatible nozzle types.

Equipment Modifications

There are several ways you can adjust your spray equipment to reduce driftable fines. Decreasing the distance from the spray canopy will reduce drift; however, applicators must stay within a select range from the spray canopy to ensure their spray pattern is uniform. Lowering spray pressure creates larger droplets and therefore reduces driftable fines; however, reducing spray pressure can disrupt the spray pattern if dropped below a nozzle’s specifications (i.e. TeeJet Extended Range Flatfan nozzles must be used between 15–60 psi, or pounds per square inch). Another option to supplement other drift-reducing methods is to use shielded spray equipment, also known as wind screens or boom shields, which can reduce drift up to 70% if used properly.

Low-Drift Nozzles

Low-drift nozzles can reduce drift from 50–90% from a conventional flat fan nozzle depending on design. Low-drift nozzles produce larger droplet sizes with fewer driftable fines. Low-drift nozzles are often a good fit with systemic herbicides that do not require high coverage to be effective. There are three main types of low-drift nozzles on the market as explained below. For a more in-depth look at low-drift nozzles please read the North Dakota State University Extension Service publication titled “Selecting Spray Nozzles to Reduce Particle Drift.” This publication can be found on the MSU Extension Pesticide Education Program’s Publications and Resources webpage at: http://www.pesticides.montana.edu/reference/index.html. When determining if low-drift nozzles are appropriate for your application, contact a nozzle sales representative who can determine the best low-drift nozzle to meet your needs. Be sure to know your target output in gallons per acre (GPA), desired speed, nozzle requirements if any, and droplet size requirements as listed on the pesticide product label.

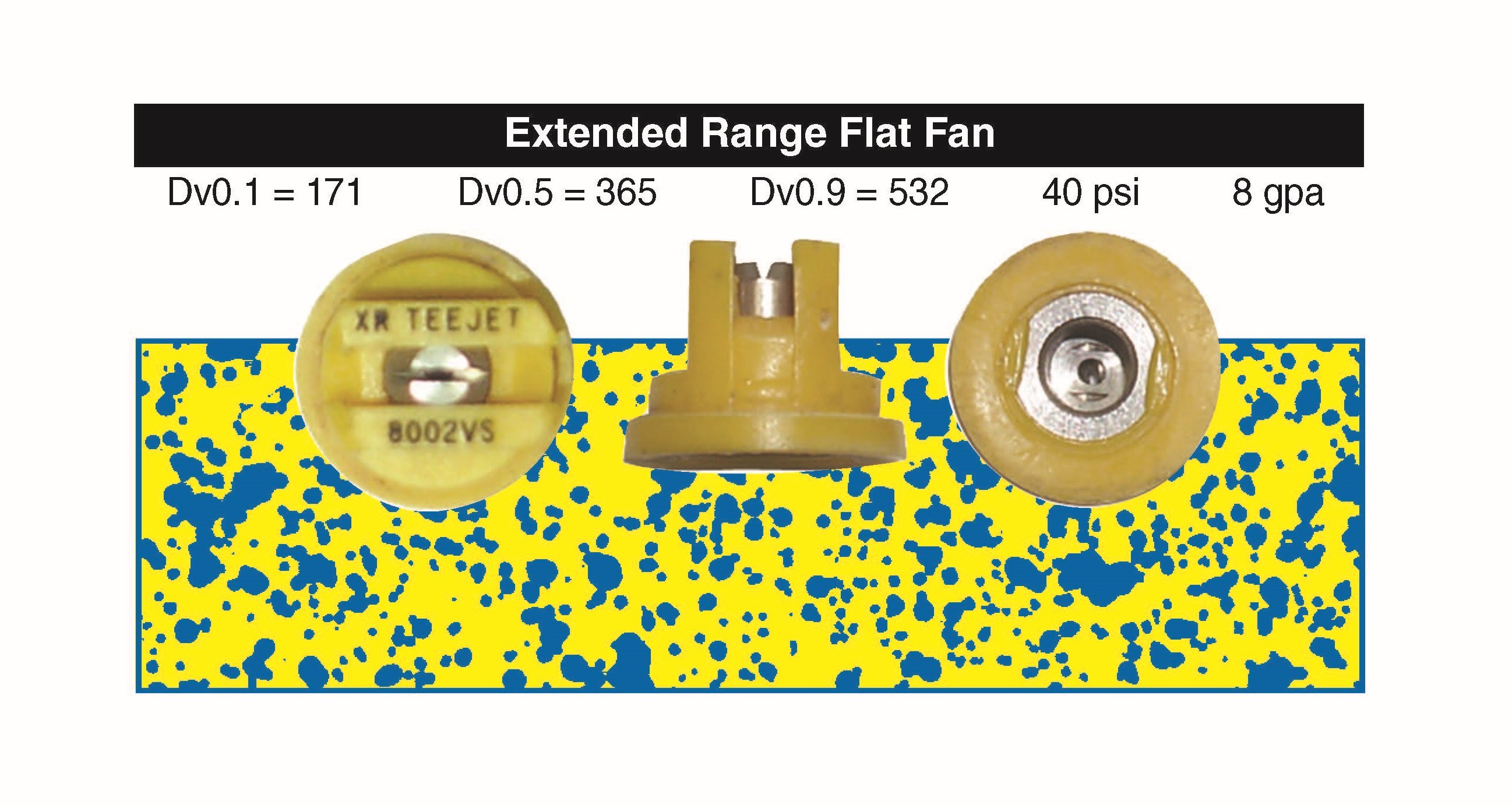

Conventional Nozzle/Extended Range Flat Fan Nozzles

Extended range flat fan nozzles (Figure 7) are conventional nozzles available in a wide range of flow rates and angles. These nozzles spray fine to very coarse, average particles depending on nozzle size and pressure while offering good coverage. Smaller nozzles produce smaller particles (fine to medium) while larger nozzles produce larger particles (medium to very coarse). While this nozzle is not considered a low-drift nozzle due to the abundance of driftable fines; you can reduce driftable fines by decreasing the spray pressure (lower than 30–40 psi). They can be used from 15–60 psi.

Figure 7. The Extended Range Flat Fan nozzle can be used at low pressures to decrease droplet size with high coverage (NDSU).

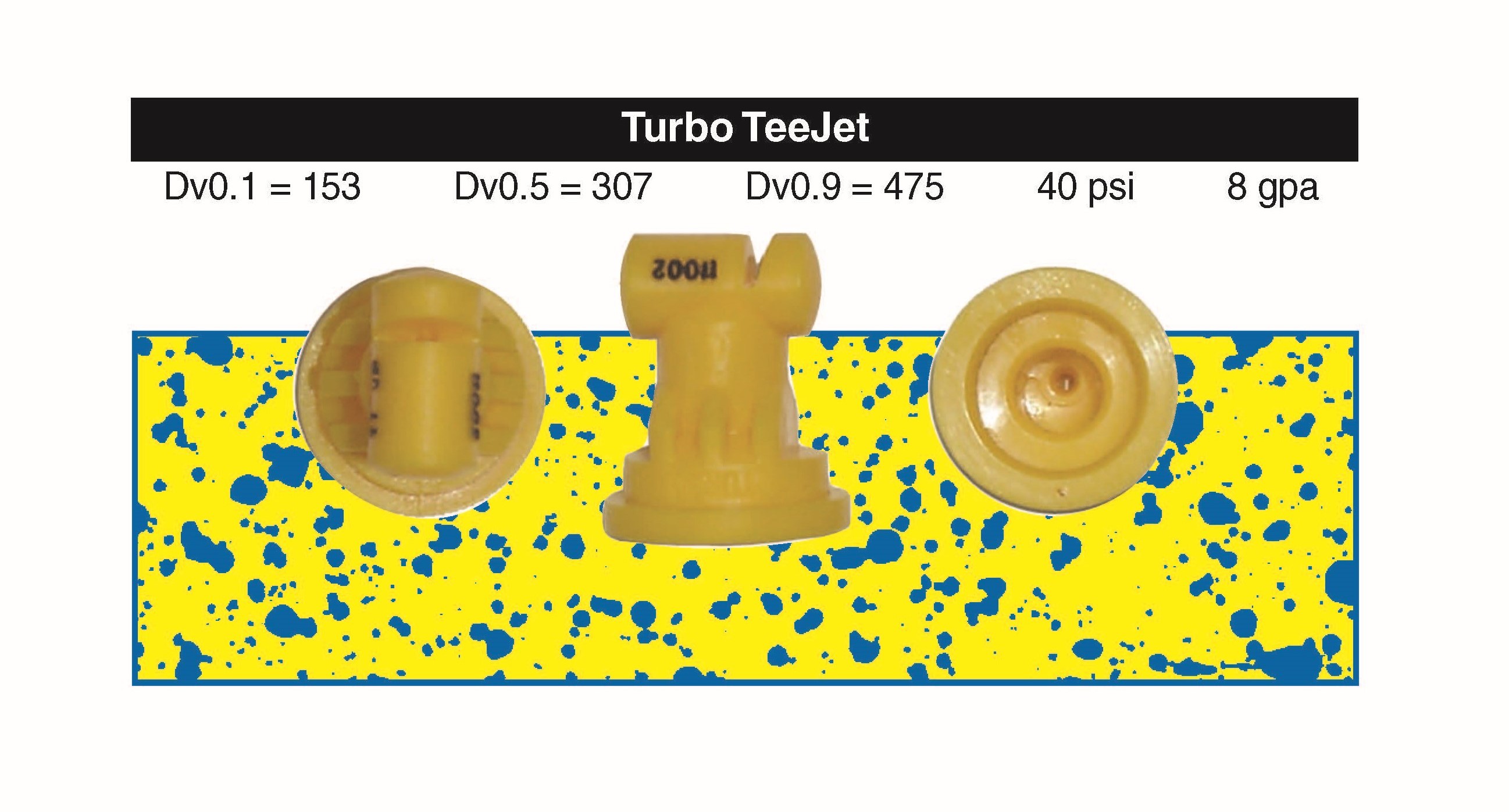

Chamber Design Drift Reducing Nozzles

Turbulence chamber design nozzles (Figure 8) or pre-orifice nozzles have pressure-reducing chambers which increase droplet size leading to less driftable fines than conventional nozzles. These nozzles operate over a wide range of pressures (15–90 psi) with average droplet sizes from medium to extremely-coarse. One example is the Turbo TeeJet nozzle that can reduce drift by 50% compared to the extended range flat fan nozzle.

Figure 8. The Turbo TeeJet nozzle can reduce drift up to 50% when compared to conventional nozzles, while offering moderate coverage (NDSU).

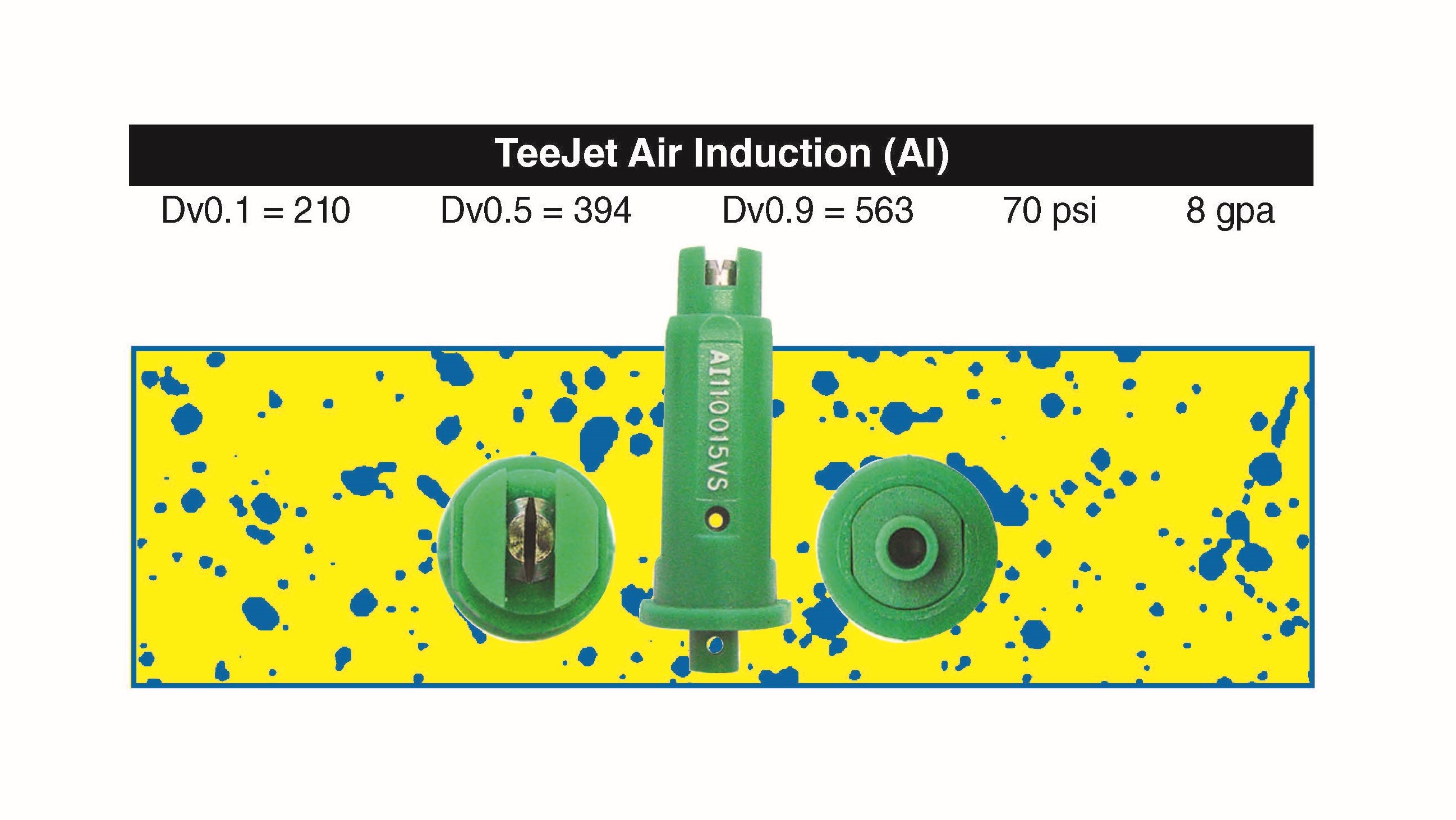

Venturi or Air-Induction Nozzles

Venturi or air-induction nozzles (Figure 9) are designed with two chambers, one to regulate liquid flow and the other to form the spray pattern. These nozzles insert air into the liquid spray droplets to increase overall droplet size and reduce driftable fines. Venturi nozzles decrease drift by 50–90%, depending on the model compared to conventional nozzles. The large droplets shatter on impact, increasing the coverage. Most venturi nozzles range from coarse to ultra-coarse droplets using pressures from 40–100 psi, however, newer venturi nozzle designs offer smaller droplet ranges with pressures as low as 15 psi. Venturi nozzles with coarser droplets have low coverage while those producing smaller droplets have increased coverage. Ensure your equipment can maintain pressures necessary for venturi nozzles.

Figure 9. The TeeJet Air Induction (AI) nozzle is an example of a Venturi Air-Induction nozzle. This type of nozzle can greatly reduce drift but has low coverage (NDSU).

Summary

- Read and follow pesticide product label requirements;

- Prior to spraying conduct a site assessment for sensitive sites which could be impacted by drift;

- Use buffers around sensitive sites and spray these areas first before afternoon winds pick up and increase drift;

- Be aware of water bodies including storm drains, ditches, and surface water;

- Use wind to your advantage if blowing away from sensitive sites;

- Spray in the morning for the best conditions when there is not an inversion;

- Apply during calm weather conditions;

- Select low volatile pesticides that permit the use of larger droplet sizes to decrease drift;

- Keep in mind, choosing drift-reducing technology (i.e. drift reducing nozzles, drift reducing adjuvants, windscreens, etc.) does not mean all drift will be eliminated. Non-target impacts can still occur if you are spraying in inappropriate conditions or if sensitive sites are downwind.

Information and Resources

MSU Extension Pesticide Education Program

406-994-5067 or 406-994-5178

[email protected]

https://www.montana.edu/extension/pesticides/index.html

Common chemical, pesticide trade names and drift reducing technologies are used in

this publication for clarity of the reader. Inclusion of a common chemical or trade

ename does not imply endorsement of that particular product

or brand and exclusion does not imply non-approval. Pesticide applicators should always

follow the product label.

We encourage the use of this document for nonprofit educational purposes. It may be used or reprinted if no endorsements of a commercial product, service or company are stated or implied, and if appropriate credit is given to the authors and MSU Extension. Permission must be sought from the MSU Extension Distribution Center, 135 Culbertson Hall, Bozeman, MT, 59717-2040. Email [email protected] or telephone (406) 994-3273.

The U.S. Department of Agriculture (USDA), Montana State University and Montana State University Extension prohibit discrimination in all of their programs and activities on the basis of race, color, national origin, gender, religion, age, disability, political beliefs, sexual orientation, and marital and family status. Issued in furtherance of cooperative extension work in agriculture and home economics, acts of May 8 and June 30, 1914, in cooperation with the U.S. Department of Agriculture, Cody Stone, Director of Extension, Montana State University, Bozeman, MT 59717.